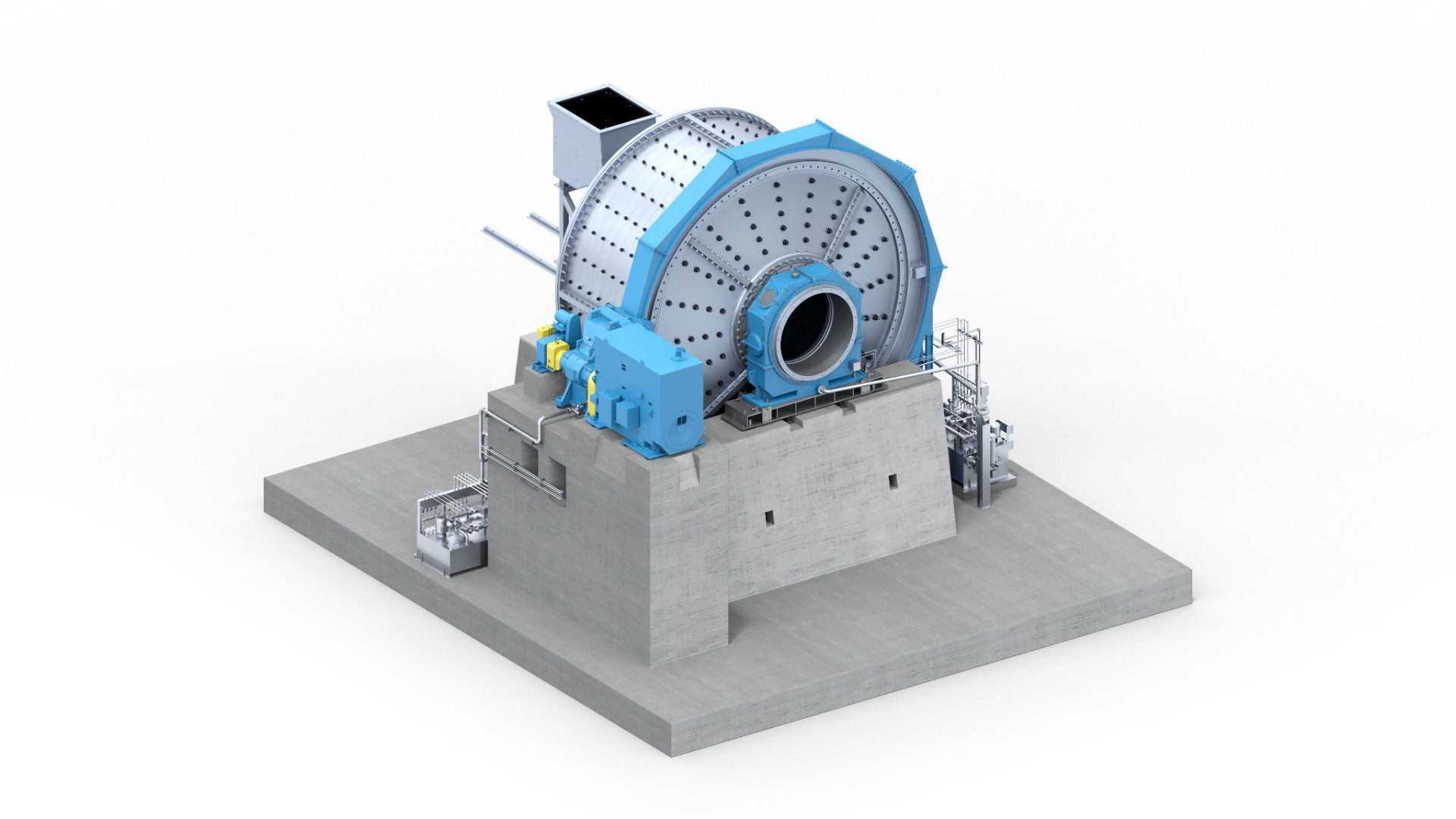

Semi Autogenous Grinding – SAG

Benefits of cutting-eBenefits of cutting-edge SAG and AG mill designs, engineered for robustness and optimized for high availability

Experience the efficiency and reliability of our robust autogenous and semi-autogenous mills, which surpass conventional secondary and tertiary crushing circuits by achieving higher throughputs.

With combining crushing and grinding capabilities, our SAM Benefits of cutting-edge SAG and AG mill designs, engineered for robustness and optimized for high availability

Experience the efficiency and reliability of our robust autogenous and semi-autogenous mills, which surpass conventional secondary and tertiary crushing circuits by achieving higher throughputs.

With combining crushing and grinding capabilities, our SAM mills streamline your grinding operations.

Autogenous mills provide a cost-effective alternative without compromising performance. Powered by rotary motion, the material is effortlessly lifted, crushed, and comminuted by itself. Semi-autogenous mills operate by incorporating the use of steel grinding media, typically ranging between 8% and 15% of the mill volume.

In many scenarios, ball mills are utilized for further processing of the product from autogenous (AG) or semi-autogenous (SAG) mills. However, there are instances where single-stage AG/SAG mills can already achieve the desired final fineness, eliminating the need for additional grinding stages.

Discover the next level of grinding excellence with our advanced mill solutions.